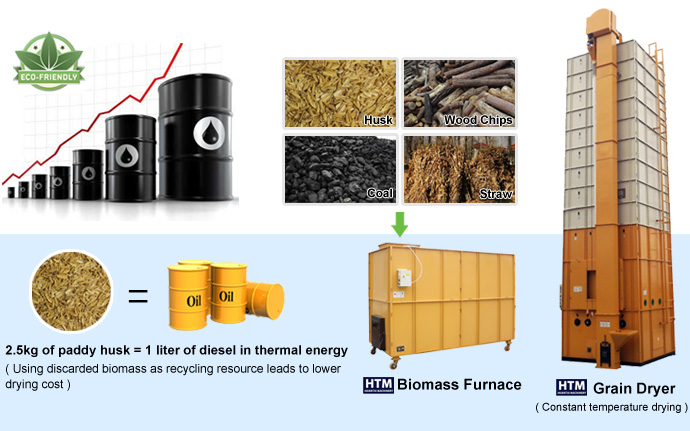

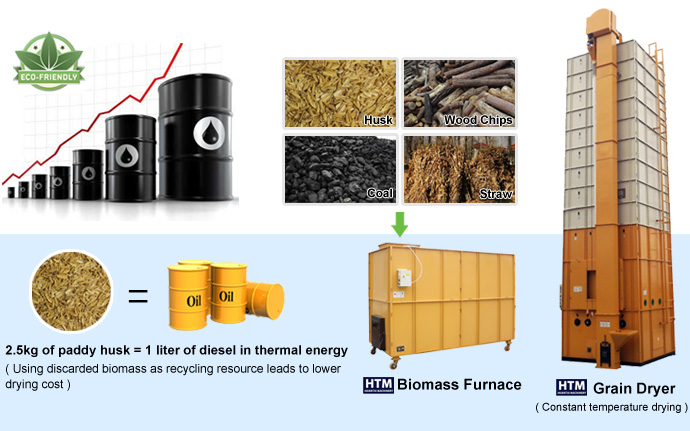

Use Biomass Grain Dryer to Beat Rising Fuel Prices, Save Drying Cost !

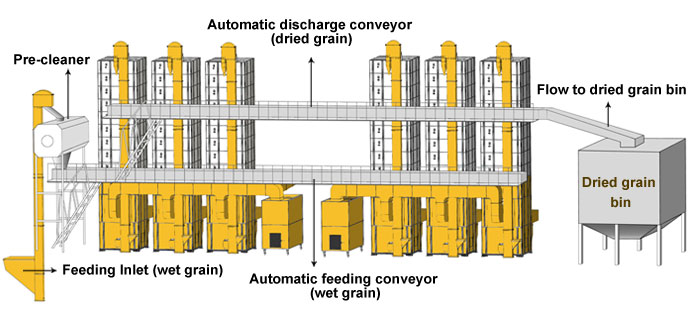

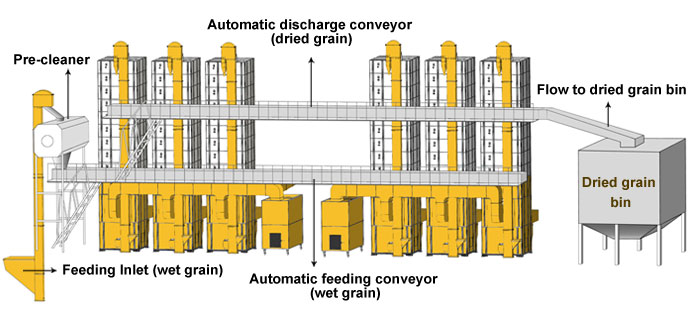

Construction

Biomass Grain Dryer

Use renewable biomass fuels to dry paddy, wheat, corn and soya bean etc. lowest drying cost, best grain quality after drying.

Features:

1. Using Automatic Feeding & Drying & Discharging System for increased efficiency for improved productivity and labour efficiency.

2. Using online computerized moisture meter, monitor the paddy moisture content in real-time, it can ensure good quality grain & prevent over-drying

3. Automatic temperature controlling System, equip with grain temperature sensor to control drying temperature exactly. 4. Fast heating speed & High thermal efficiency.

5. Indirect hot air to ensure the grain dries evenly and cleanly.

6. Easy operation and maintenance, no needs for professional technicians.

Specification of Paddy Dryer:

|

Model Item

|

HG10 |

HG12 |

HG15 |

| Loading capacity (kg) |

Paddy (kg)

(1 Liter= 560g ) |

2300 ~ 10000 |

2300 ~ 12000 |

2300 ~ 15000 |

|

Wheat (kg)

(1 Liter= 680g ) |

2700 ~ 12100 |

2700 ~ 14500 |

2700 ~ 18200 |

| Performance |

Feed Time

(Min) |

Paddy |

45 ~ 55 |

50 ~ 60 |

70 ~ 80 |

| Wheat |

40 ~ 50 |

50 ~ 60 |

70 ~ 80 |

|

Outlet Time

(Min) |

Paddy |

40 ~ 50 |

45 ~ 55 |

65 ~ 75 |

| Wheat |

35 ~ 45 |

45 ~ 55 |

65 ~ 75 |

| Drying capacity (kg.) |

7800 |

8000 |

9000 |

| Internal volume (m³) |

18.53 |

23.96 |

27.18 |

| Outside dimension L*W*H (mm) |

4828*2492*7436 |

4828*2492*8750 |

4828*2492*9556 |

| Packing dimension L*W*H (mm) |

2100*2080*6602 |

2100*2080*7916 |

2100*2080*8722 |

| Net weight (kg) |

2700 |

2800 |

3000 |

| Power (Kw) (Excluding Burner) |

6.8 |

6.8 |

6.8 |

| Standard Devices |

Online computerized moisture meter, Grain temperature sensor, Fault sensor etc |

| Safety Devices |

Full load alarm device, Thermal relay, Temperature controller, Abnormal combustion sensor, Overload protection device, Earth leakage protection device. |

|

Centrifugal

fan |

Rated air volume(m³) |

6677 ~ 13353 |

| Air outlet diameter(mm) |

600 |

| RPM |

1450 |

Drying rate list is for reference only. Actual data will differ by ambient temperature, relative humidity, grain variety, hot air temperature, moisture rate before and after drying.

Biomass Furnace

Specification:

|

Model Item

|

RFL20 |

RFL30 |

RFL40 |

| Biomass fuel |

Paddy Husk / Wood Chips / Straw / Coal |

|

Fuel consumption

volume

(kg/h) |

Paddy husk |

25~35 |

45~55 |

55~60 |

| Wood chips |

27~38 |

49~60 |

55~65 |

| Straw |

45~50 |

55~60 |

65~75 |

| Coal |

13~18 |

23~28 |

30~40 |

| Thermal energy volume (Kcal/hour) |

20 |

30 |

40 |

| Output hot air volume (m³/h) |

6,700~13,350 |

13,350~26,700 |

26,700~40,000 |

| Output hot air temperature |

≤ 150 |

| Heating type |

Indirect hot air & Automatic temperature controlling |

| Ignition |

Manual |

| Feeding type |

Automatic Feeding (husk) |

| Blower type |

4-72-3.2A |

| Outside dimension L*W*H (mm) |

2800*1300*2300 |

3100*1400*2300 |

3200*1600*2300 |

| Net weight (kg) |

2800 |

3200 |

3400 |

| Power (Kw) (Excluding Burner) |

1.5 |

2.2 |

2.2 |

| Dryer Matching |

HG10 – 1 unit |

HG10 – 2 units |

HG10 – 3 units |

| HG12 – 1 unit |

HG12 – 2 units |

HG12 – 3 units |

| / |

HG15 – 2 units |

HG15 – 3 units |

| Safety Devices |

Thermal relay, Automatic temperature controller, Abnormal combustion sensor, Hot air sensor, Overload protection device, Earth leakage protection device.

|